Ace Precision is recognized for responsiveness and reliable quality.

We manufacture the following products, controlling and executing the entire process in-house:

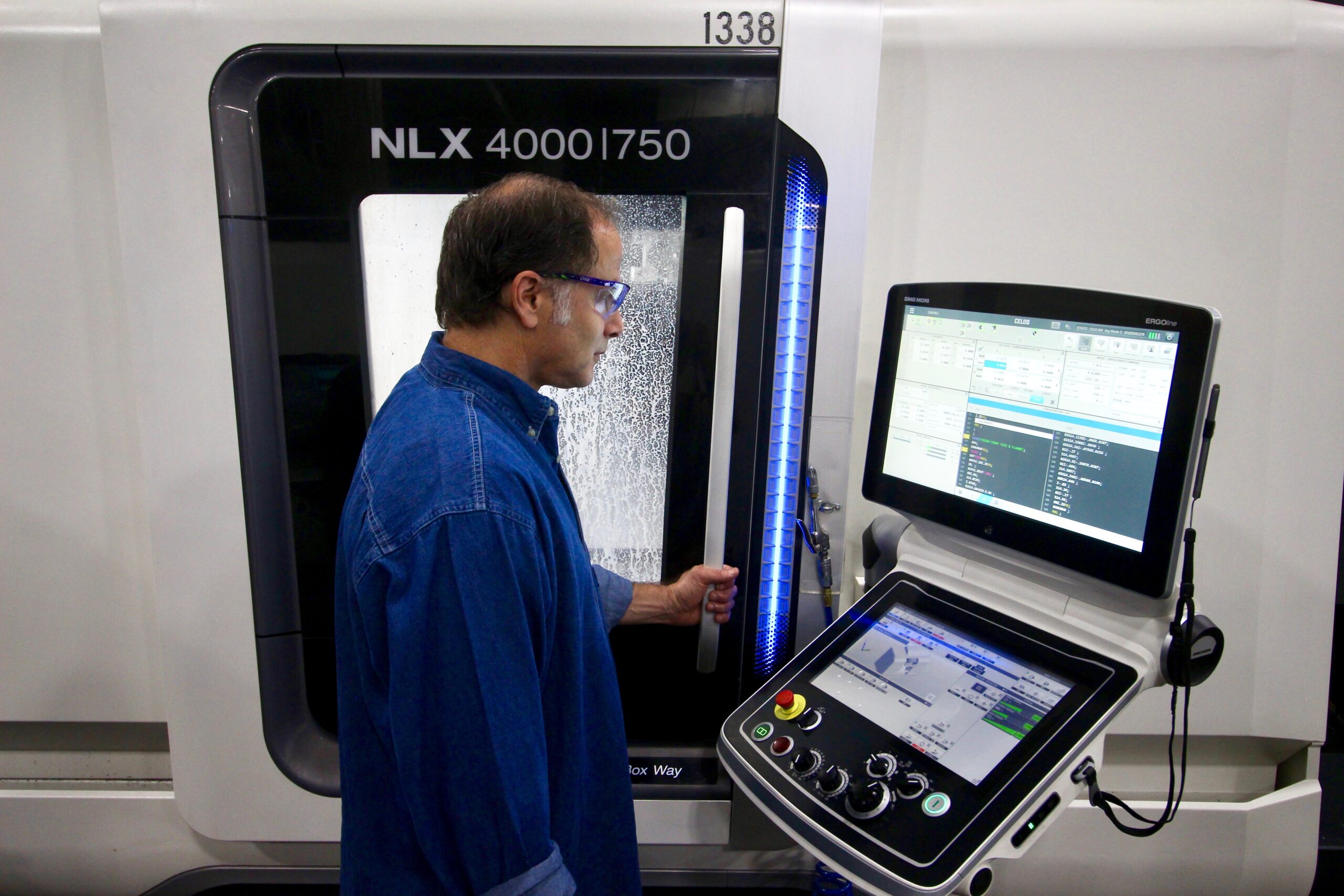

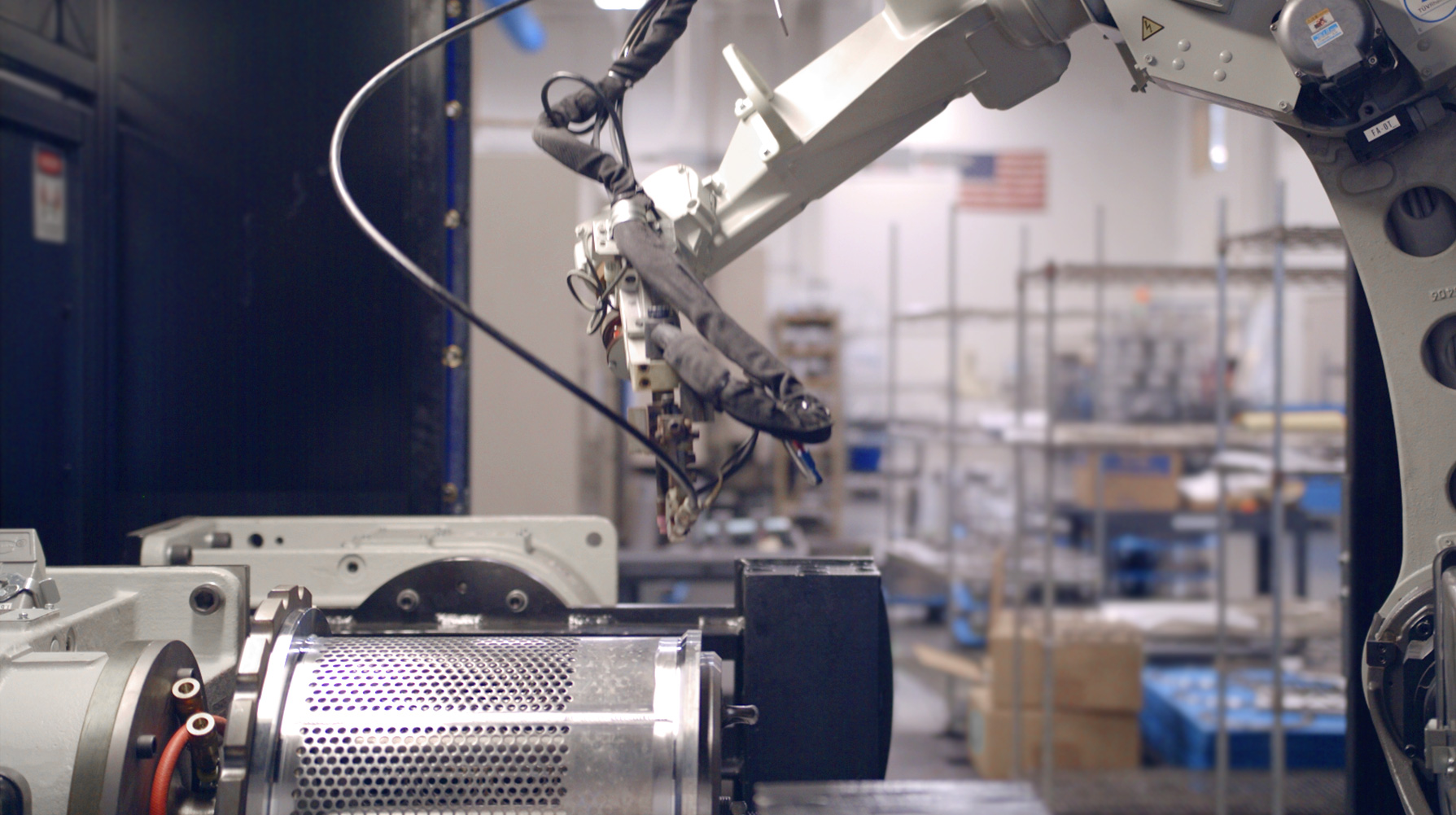

Ace Precision has been a premier supplier of aerospace OEM gas turbine engine components for over 30 years. Our staff has extensive industry knowledge of both legacy products and emerging technologies. With a wide range of special processes in-house, Ace Precision is ready to take on complex assemblies that would be a challenge for our competition.

We manufacture the following products, controlling and executing the entire process in-house:

The components we manufacture are critical to the safe operation of small propulsion engines for business jet, helicopter and military aviation applications, as well as auxiliary power units (APUs) for large commercial operators and the regional jet market. We work with a wide variety of materials, including aluminum, nickel, and cobalt-based high temperature alloys in sheet stock, castings and forging material forms. Please see “Capabilities” for specific insight into the metal forming, joining, coating, and wide array of vertically integrated processes we perform.

Our customer base includes Honeywell, Rolls-Royce, StandardAero, and domestic and international airlines. We develop close business and working relationships with our customers, collaborating to improve quality, eliminate waste, cut costs and reduce lead times.