Hydroforming

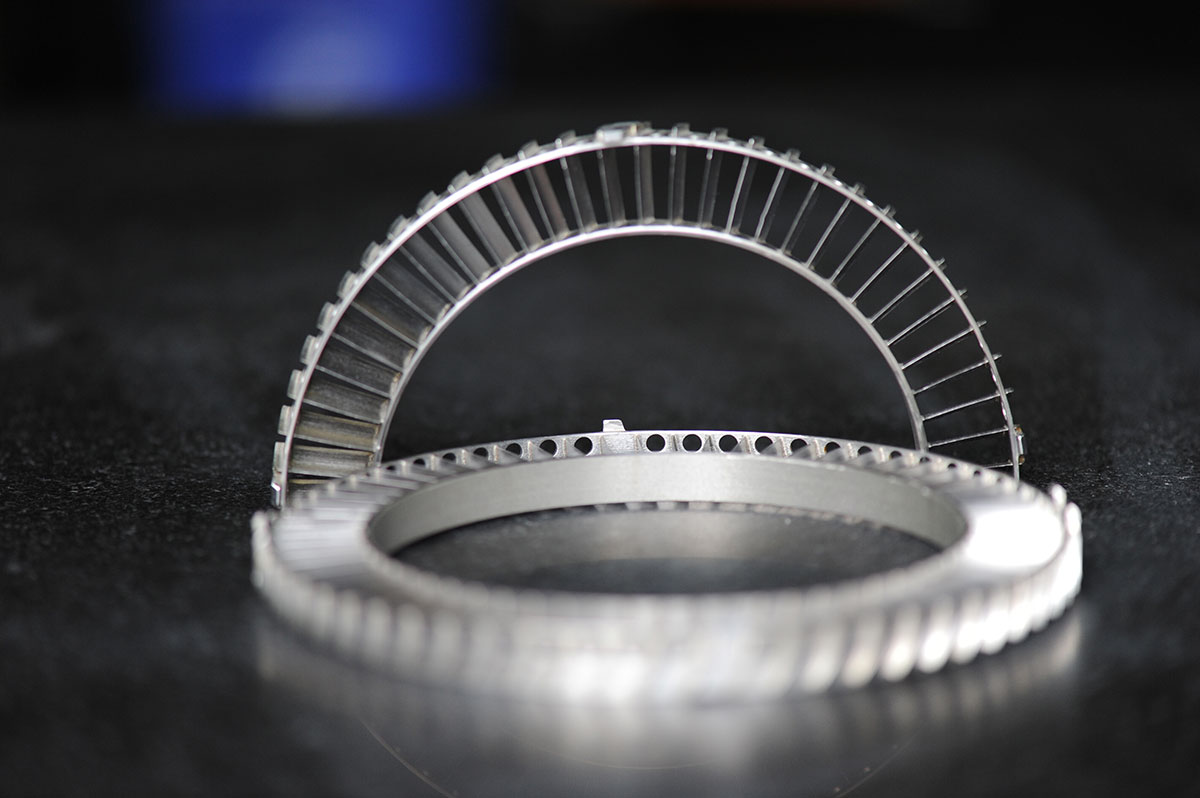

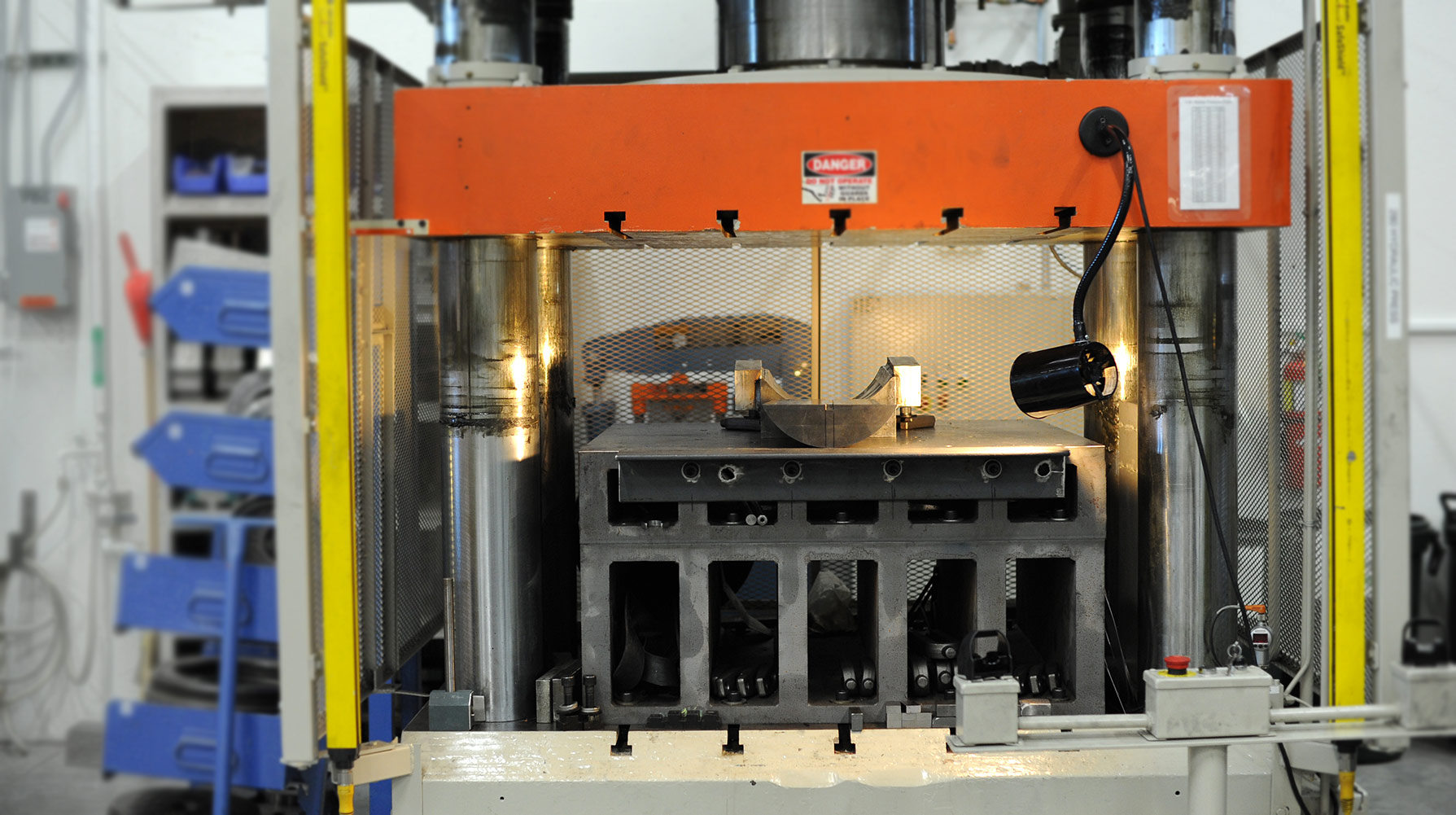

Always seeking to increase our in-house capabilities, Ace Precision purchased a Triform hydro-forming machine, with a larger working envelope and a maximum blank size of 25″. This new technology provides a stepwise application of hydraulic pressure, providing more draw depth per operation at a lower cost. The Triform joins our existing pair of 15″ hydro-form machines – all capable of 10,000 PSI. The smaller, continuous draw machines use dynamic punch techniques to meet a variety of forming requirements, while capitalizing on faster production rates. Benefits of hydroforming include: economical tooling, efficient production rates, and the ability to hold close tolerances on a variety of intricate shapes. Materials can be drawn slowly allowing the material to flow, which helps avoid cracking and tearing. Generally, our parts have two draws and an in-process anneal to set the material.